Characteristics and properties

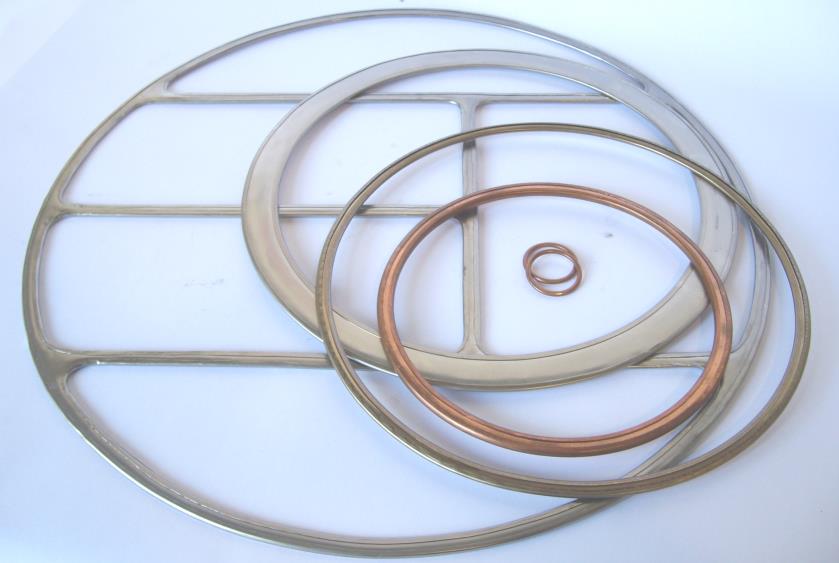

Of metal seals, are composed of a soft core, usually graphite, but also free asbestos or fiberglass or p.t.f.e., partially or totally covered by a metal sheath. These types of gasket, which is not more easily collapsible corrugated metal types, resist high pressures and temperatures and can be used in various operating conditions with an appropriate choice of the constituent metal sheath. Are produced in various shapes: circles, circular, with one or more stringers as from the following table, oval, square,

diamond, pear, oblong etc. Regarding the size, there is theoretically no limitations. The standard thickness of these seals is 3 mm. But according to use can be thick as 4.5 or even 6 and 8 mm.